Why ICE Panels?

Build It Smarter. Build It Better.

Build It With ICE Panels.

HIDDEN ITEM

Enhanced Well-being

We don’t realize we care about comfort until we’re uncomfortable. ICE Panels provide a structurally sound, air-tight building envelope that provides comfortable, healthy, and efficient living spaces.

SAFETY: ICE Panels are crafted and assessed to meet stringent code requirements and safety standards, used only where they’ve confirmed to be safe and effective. In 2019, during Hurricane Dorian’s strike on the Bahamas, the ICE Panels demonstrated their durability and resilience. Despite other structures on Grand Bahama island being destroyed, our project remained intact, exhibiting its intended strength and reliability.

COMFORT: ICE Panels contribute to an airtight building envelope, which means it will be draft-free and easy to keep at a comfortable temperature all year round, no matter what weather conditions you face.

HEALTH: Indoor air quality is more important than ever to the modern consumer. ICE Panels are built using materials that do not off-gas, do not contribute to, or support mould and mildew growth, and will not rot or decay, contributing to toxic indoor air quality.

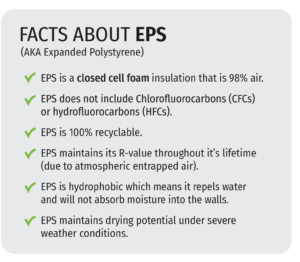

NO OFF-GASSING: Many insulations inflate R-values using toxic gases, neglecting years of off-gassing which reduce the real R-value. This led to the term “Long Term R-Value” (LTR). Some foam insulation types are made via a chemical reaction that fills foam cells with artificial gas, causing toxic off-gassing and R-value reduction. EPS uses atmospheric air, preventing toxic off-gassing and maintaining long term R-value.

AIRTIGHT BUILDINGS: Leaky buildings cause drafts and discomfort, leading to poor sleep and stress. Sealing the building and managing air exchanges through specific points allows for proper air conditioning to the right temperature and humidity. This provides an evenly heated home and a comfortable, stress-free environment.

BETTER WALLS: Mould in exterior walls is common due to open cell insulations that trap moisture. With tighter building standards, this water doesn’t dry out, causing mould and premature rotting of organic components inside the walls. ICE Panels, made with steel framing and closed cell insulation called expanded polystyrene (EPS), neither rot nor support mould growth in high moisture environments. EPS can wick away any condensated moisture, making it a self-drying insulation. This results in longer lasting buildings with healthier indoor air quality.

Financial Freedom

Building with ICE Panels is an upfront investment. Building with a new product may sound costly, but there are many ways you will save money, not only during the construction phase, but after — during the lifespan of the build.

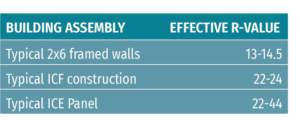

R-VALUE: Lower your monthly bill by conserving energy with modern construction methods. ICE Panel’s superior performance offers the industry’s lowest cost per R-value, significantly reducing utility costs.

ENERGY EFFICIENCY: Traditional buildings lose heat through thermal bridging. ICE Panels are thermally broken, eliminating most thermal bridging for a highly efficient envelope and monthly utility savings.

AIRTIGHTNESS: With ICE Panels, your building is airtight. Outside air is kept out, preventing drafts and lowering heating and cooling bills.

MORE SQUARE FEET: Use ICE Panels for a thinner, higher performing wall, adding extra square footage and increasing resale value.

LESS WASTE: Less material waste reduces construction costs and cleanup time – a frequently overlooked saving.

LESS CONSTRUCTION HEATING: In cold climates, ICE Panels save on hoarding and heating expenses as they arrive pre-insulated and vapour tight.

SHORTER BUILD TIMES: Building with ICE Panels guarantees faster close-in times, so whether its your family or a paying tenant moving in, 30 days advanced occupancy means 30 days of saved time and resources that can be allocated to other projects.

REBATES AND INCENTIVES: ICE Panels contribute to new construction rebates and incentives eligibility. They’ve helped achieve Step 5 of the BC Energy Step Code, qualifying projects for up to $10,000 per unit. An energy advisor can provide a projection of energy conservation using an ICE Panel building envelope.

Sustainable Living

A carbon-neutral future requires advancement in technology. By focusing on the performance of our buildings, we can make an impact on overall energy consumption. The ICE Panel is a building envelope technology that bridges the gap between sustainability and economics.

Accelerated Completion

By combining three construction steps into a simple, prefabricated solution, the ICE Panel allows for faster completion.

SIMPLIFIED CONSTRUCTION: ICE Panels integrate framing, insulation, and vapour barrier in a single on-site process, saving time and money compared to traditional methods. This shortened time frame equals savings in construction financing, and possibly extra revenue generated due to earlier occupancy.

FASTER CLOSE IN TIMES: ICE Panels hasten project closure, reducing vulnerability to weather elements and improving quality control. They also reduce the risk of material damage during winter construction.

COORDINATION: Greenstone uses REVIT 3D modeling for all projects, pre-fitting intersecting geometries including components from other suppliers. This leads to precise construction, often eliminating costly errors.

WORK SMARTER: Being lightweight, ICE Panels can be installed without heavy machinery, reducing crew fatigue and strain from lifting heavy materials.

CLEAN JOBSITE: Factory post-processing of ICE Panels eliminates most shipping waste. On-site modifications are reduced by framing rough openings and cutting angles during manufacturing, boosting productivity by reducing cleanup and travel time.

Engineered Quality

Every ICE Panel project is reviewed by a certified structural engineer, providing a high level of quality assurance.

ENGINEERED SIGN-OFF: Greenstone offers engineering services for the ICE Panel segment of projects. This includes a final installation review and sign-off, verifying correct assembly and installation in line with the engineer’s specifications.

CONSISTENT CONSTRUCTION: Mass production of lumber materials can lead to questionable quality. Twisted lumber is common on job sites, which could compromise building quality over time. As an engineered product, ICE Panels are manufactured for precision and consistency, facilitating easy, accurate construction.

PRECISION BUILDING: Greenstone develops a REVIT 3D model for each project, pre-fitting all intersecting geometry, including components from other suppliers. This preemptive approach allows Greenstone to catch errors before any components are produced, ensuring extremely precise construction and saving potential costs.

STRONG: ICE Panels are used in seismic and hurricane zones due to their lightweight yet high elastic strength. They have proven successful in both extremes, demonstrated in The Bahamas during hurricane Dorian in 2019.

LIGHTWEIGHT: Composites, like ICE Panels, are known for being lightweight and strong. Replacing concrete with ICE Panels significantly reduces building weight and the load on supporting foundations, often resulting in substantial cost savings.

Peace Of Mind

New construction is a big undertaking. Choosing a building product that streamlines the process is a huge win. Investing in a prefabricated product makes all the difference. Build it with ICE Panels and enjoy the simplified process.

MORE SQUARE FEET: ICE Panels allow for energy-efficient buildings with thinner walls, resulting in extra occupiable space. More space means higher revenues and resale value.

APPEARANCE: ICE Panels afford design flexibility without compromising on energy efficiency, creating attractive buildings that appeal to renters.

COLLABORATION: We’re always ready to collaborate on technical calls and design discussions to ensure component suppliers understand how their parts fit with ICE Panels.

AIRTIGHTNESS: ICE Panels create an airtight building envelope thanks to the Expanded Polystyrene (EPS) insulation. Sealed panel joints make the building highly airtight, ensuring comfort and low energy usage.

ENGINEERED SIGN-OFF: Greenstone offers engineering services including final installation review and project sign-off for ICE Panels, ensuring they are correctly installed as per the specifications.

UNWAVERING PROJECT SUPPORT: Greenstone provides technical support to tackle any complications efficiently. Our aim is to keep your project on track and make your ICE Panel experience stress-free.